-

BK: black powder coated surface

-

SV: white galvanized surface containing chrome, also suitable for ESD use

-

NI: nickel-plated surface without chrome, also suitable for ESD use

Accessories

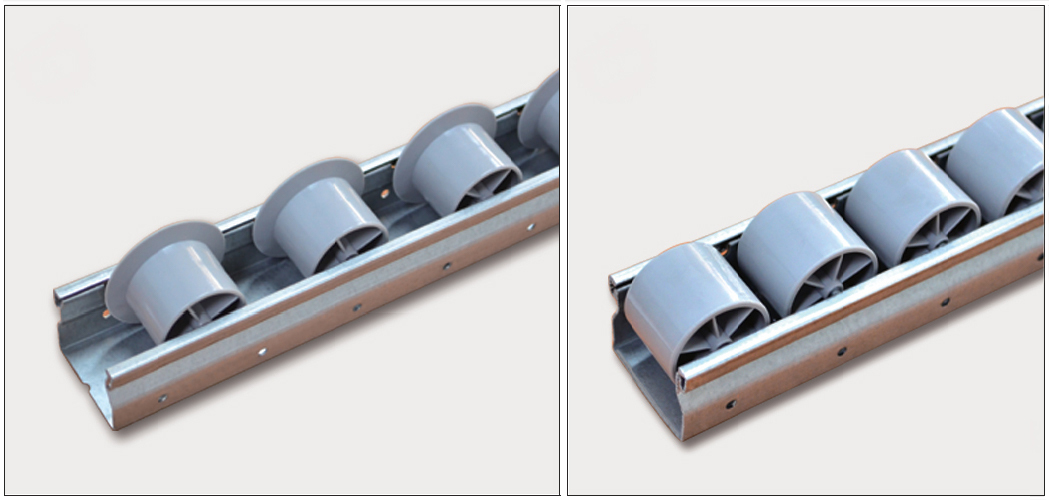

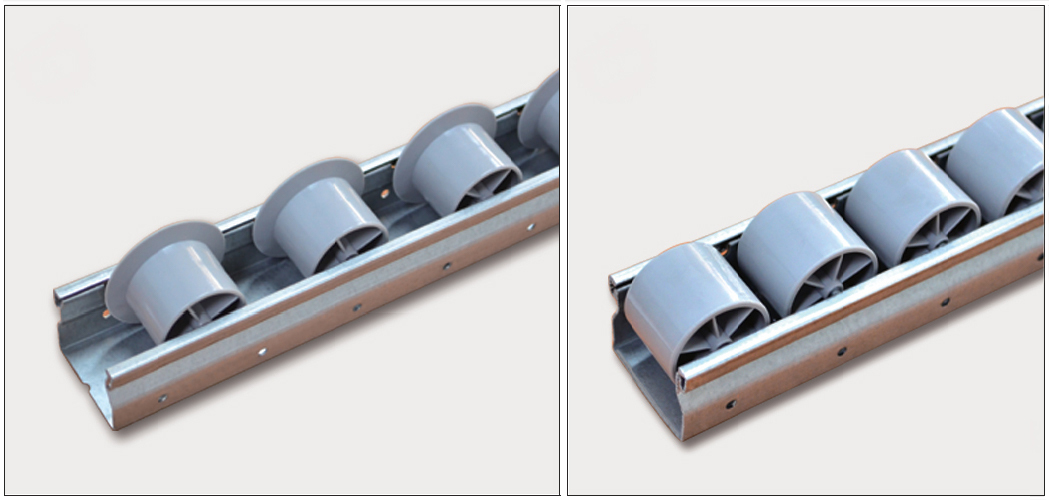

In addition to the pipes and couplings themselves, we also offer a wide range of accessories and accessories. With the help of these accessories, a complete and fully functional design can be created that exactly meets the needs of your specific application. Roller tracks are a frequently used element of the tubular modular system. These facilitate the smooth flow of material and help optimize inventory handling. They are a key building block in the creation of FIFO racks (First in, First out) and flow racks, which enable organized and continuous movement of materials.

Purchase options for structural systems

Purchase of the material itself: You can choose the pipes, couplings and other components according to your specifications and needs, without cutting or other modifications.

Purchase of cut material: We also offer the option of purchasing already cut pieces of material that are ready for assembly. Customers get exact parts, which they then assemble themselves into the desired structure.

Finished and already assembled constructions: We provide the option of purchasing already finished and completely assembled constructions. These products are ready for immediate use and can be immediately integrated into your operations or projects.

Construction from the modular system

A wide variety of structures can be created from the tubular modular system. The most common use of this system:

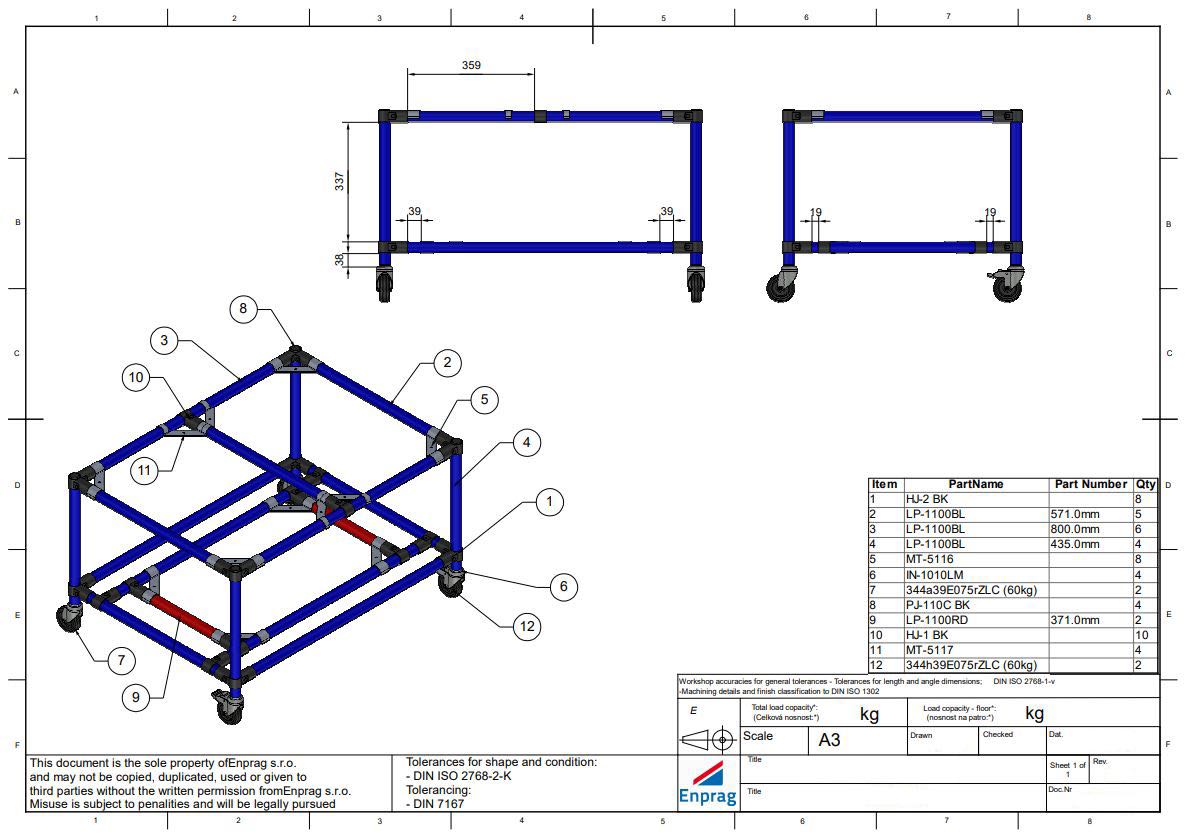

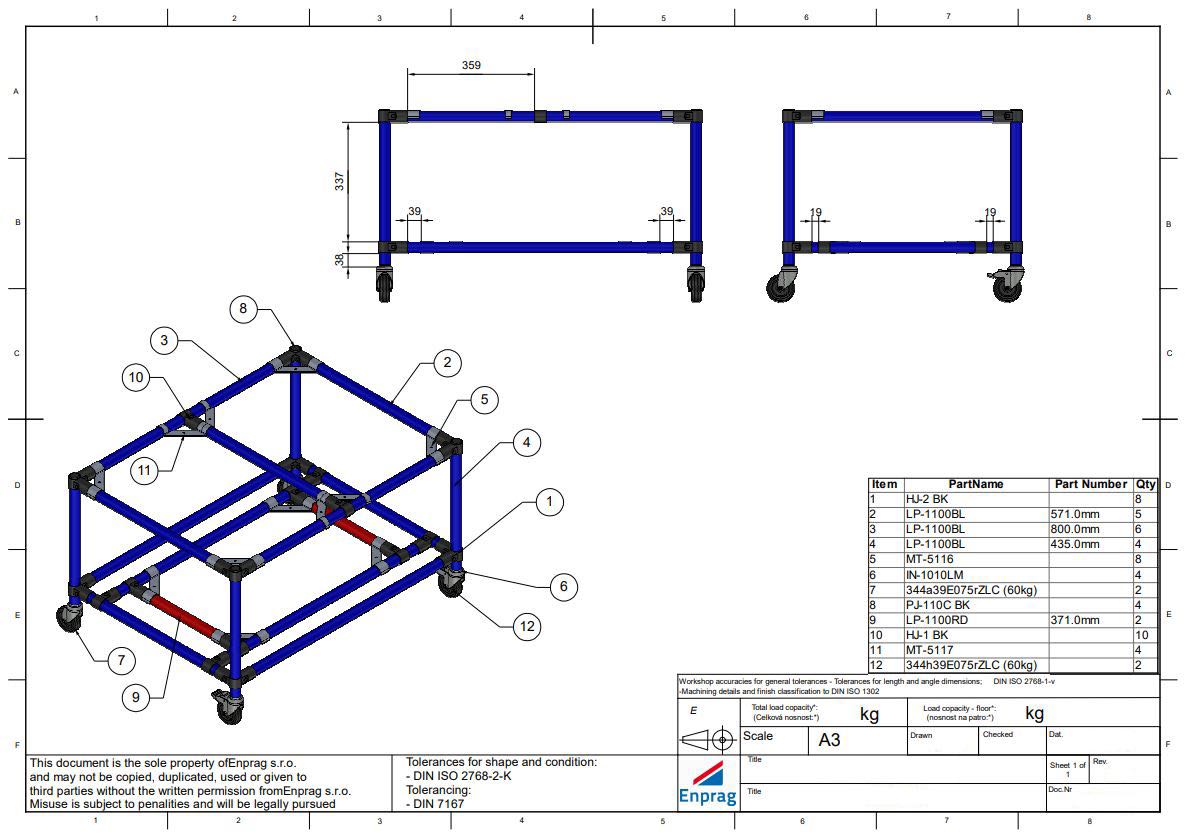

Handling trolley

Handling carts are structurally simple, but very useful and practical tools for transporting products. There are many different types of transport carts that differ in height, width, length or load capacity. Some transport carts have a perforated panel body or an integrated workshop container that allows for the organization of important pieces of tools. In addition, you can buy organizers for drawers to facilitate storage.

Falling shelf

Thanks to its lightness and flexibility, the tube system is also suitable for drop shelves. With the help of this system, e.g. boxes with products are inserted from one side, which, after being set up, go down to the end of the roller track so that they are unloaded from the other side of the shelving system. This process effectively uses the FIFO (First In, First Out) principle, which ensures the systematic removal of goods.

Workshop tables

This system is also a great base for building workshop tables. All workplaces are designed and constructed to suit a specific production process. Thanks to workplaces assembled from a tubular modular system, it is possible to reduce the space of the work surface to the necessary minimum. Each workplace can be equipped with perforated panels with hangers for storing tools or for hanging plastic boxes. Workshop table containers can also be included.