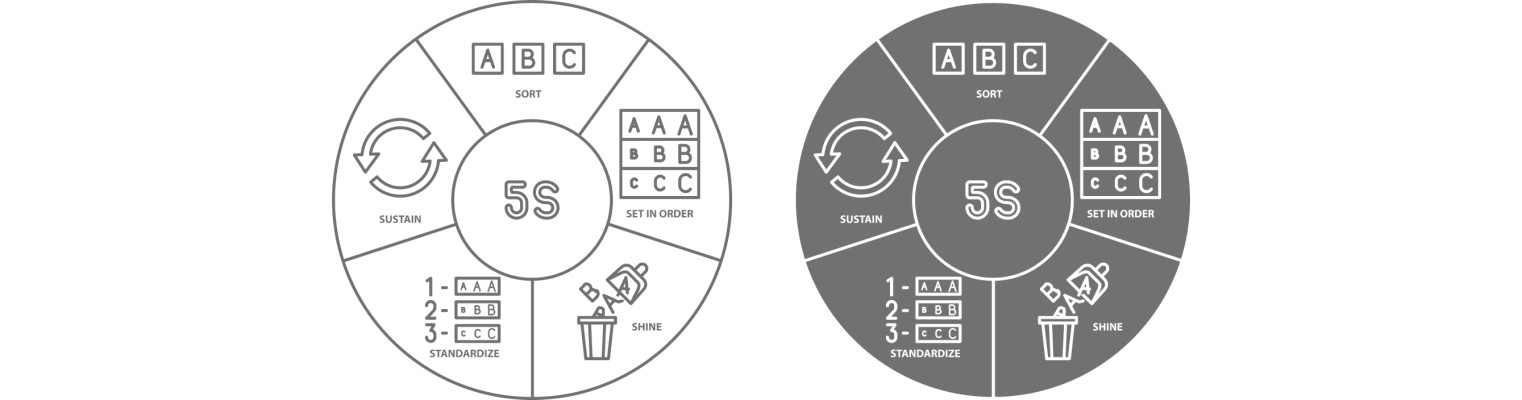

The 5S method is the result of a commitment to remove unnecessary items from workstations, ensure order, cleanliness and instill methodical discipline across processes using Japanese philosophy:

- Seiri: Sort out, eliminate the unnecessary

- Seiton: Organize, a place for everything and everything in its place

- Seiso: Clean, keep clean, remove from sources of impurities

- Seiketsu: Standardization. Flat application of cleanliness and order

- Shitsuke: Maintenance. Permanent support for joint compliance with established rules